Kink of Yarn: This refers to a length of yarn bent into a specific shape, making it ready to be transformed into a weft-knitted loop.

Knitted Loop: When two kinks of yarn intermesh at their base, they form what’s known as a knitted loop.

Knitted Stitch: A knitted stitch is a basic unit in knitting. It’s made up of intermeshed loops, typically three or more, with the center loop being pulled through the head of the lower loop. This lower loop, in turn, has been intermeshed by the loop above it.

Top Arc: This is the upper curved section of a knitted loop.

Bottom Half-Arc: The lower curved part of a weft-knitted loop that connects to the adjacent loop in the same row.

Legs (or Side Limbs): These are the lateral parts of the knitted loop, connecting the top arc to the bottom half-arcs.

Needle Loop: This is the simplest unit of a knitted structure, made up of the top arc and the two legs of a weft-knitted loop. Essentially, a needle loop equals a top arc plus two legs.

Sinker Loop: The yarn portion that links two adjacent needle loops in the same knitted row. The bottom arc of a loop is often referred to as the sinker loop.

Open Loop: A loop in which the thread enters and exits on opposite sides without crossing over itself.

Closed Loop: A loop in which the thread crosses over itself as it enters and exits from opposite sides. Special needles are used to create this.

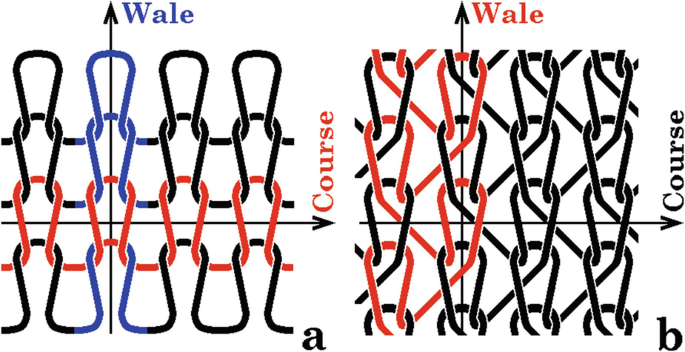

Knitted Loop Structure: The characteristics of a knitted fabric depend on how each stitch interacts with its neighboring stitches, both to the sides and above/below. Knitted loops form rows and columns, similar to the weft (horizontal) and warp (vertical) structures of woven fabrics, which are called “courses” and “wales,” respectively.

Course: In an upright fabric, a course refers to a horizontal row of loops created by adjacent needles during the same knitting cycle. In weft-knitted fabrics, the course consists of yarn from a single supply, known as course length. For more complex fabrics, a course may involve multiple yarns.

Wale: A vertical column of needle loops, created by the same needle over successive knitting cycles. In warp knitting, a wale can be made from the same yarn, forming a chain stitch. Wales are connected to each other by sinker loops or underlaps.

Stitch Density: This term refers to the total number of needle loops in a square measurement (like an inch or centimeter). It’s calculated by multiplying the number of courses and wales per inch. Stitch density gives a more accurate measurement of a fabric’s structure, as it balances out any tension differences.

Intermeshing Points (or Cross-Over Points): Each needle loop has four possible points where stitches intermesh—two at the top (head) and two at the bottom (base). These intermeshing points ensure the loops are linked, showing a face loop stitch on one side and a reverse loop stitch on the other.

Loop or Stitch Length: The length of yarn knitted into a single stitch in a weft-knitted fabric. This includes one needle loop and half of the yarn length connecting that loop to its adjacent loops. Generally, the longer the stitch, the more elastic and lighter the fabric, though it may have reduced opacity and strength.

Extended Sinker Loop: A sinker loop that’s wider than others in the fabric, often formed when a needle is inactive or removed from the needle bed.

Face Loop (or Stitch): Also referred to as a plain stitch, jersey stitch, or flat stitch, this occurs when the legs of a stitch sit above the top arc of the stitch from the previous row in the same vertical column (wale). On this side, the new loop comes toward the viewer, covering the head of the older loop. The face loop typically displays the side limbs or legs of the stitch in a series of interlocking “V” shapes. In diagrams, the face loop is often represented by the symbol “~” or “x” on graph paper.

Technical Face (or Right Side): This is the side of the fabric that, when still on the knitting needles, only shows the face stitches, which appear as a series of interlocking “Vs” formed by the legs of the loops.

Reverse (or Back Loop/Stitch): Also known as a purl stitch, this stitch is the opposite of the face loop. The top and bottom arcs sit above the legs of the previous and following stitches in the same vertical column. On this side, the new loop moves away from the viewer, passing under the old loop’s head. Reverse stitches typically showcase the sinker loops in weft knitting and underlaps in warp knitting. The reverse loop side is closer to the needle’s head because the needle pulls the new loop down through the old loop. On a diagram, this loop is represented by “3L” or “O” on graph paper.

Technical Back (or Left Side): This is the upper side of the fabric while it’s still on the needles. It primarily shows reverse stitches, which appear as sinker loops or underlaps, as well as the heads of the loops.

Double Thread Stitch: Also called a double loop or spliced stitch, this is created using two strands of yarn rather than one.

Single-Faced Structures: These are made in both warp and weft knitting when the needles, arranged either in a straight line or circular formation, operate as a single set. All needles have hooks facing the same way, with each needle pulling new loops down through the old loops in the same direction. As a result, the intermeshing points (3 and 4) are identical to intermeshing points (1 and 2).

Balanced Structure: A double-faced fabric structure where each side shows the same number and type of stitches, arranged symmetrically. This balanced arrangement typically prevents curling at the fabric’s edges.

Face and Reverse Stitches on the Same Surface: These are generally produced using purl weft knitting machines, which have double-headed needles. One needle hook draws a face stitch while the other forms a reverse stitch. This leads to variations where intermeshing points 3 and 4 may not align with points 1 and 2.

Fabric Draw-Off: Fabric is always drawn away from the needles on the side opposite the needle hooks. When two sets of needles are used (positioned either vertically or at an angle), each set’s hooks face away from the other, and the fabric is created and drawn through the space between the two sets.

Knitting Machines: These machines create fabric by intermeshing or interlooping yarn. They are categorized into three types:

- Weft Knitting Machines: These produce fabric by creating loops across the fabric’s width using yarn fed horizontally.

- Warp Knitting Machines: In these machines, loops are formed across the entire fabric width simultaneously, using yarns fed in the fabric’s lengthwise direction.

- Other Loop-Forming Machines: These machines use interlooping techniques to form fabric but don’t fit neatly into either the weft or warp knitting categories.

Needles: The core component of knitting machines, needles are responsible for forming stitches. They come in two main types:

- Independent Needles: These can slide within the needle bed and move individually during the loop formation process.

- United Needles: These are fixed in a needle bar and can only move together as a unit during the knitting process.

Needle Carrier: In knitting machines, the needle carrier holds the needles, which can move independently. These needles can either be positioned in a flat or circular bed (cylinder or dial type) or united in a needle bar.

Fabric Types: The construction of fabrics depends on the type of knitting machine:

- RL Fabric (Right-Left): This is a single-face fabric made using one row of needles.

- RR Fabric (Right-Right): A double-face fabric knitted with two rows of needles, offering a more robust structure.

- LL Fabric (Left-Left): Also known as Links-Links, this fabric is created with either one or two rows of needles, with both rows producing the same stitch pattern.

Feed System: Circular knitting machines can have up to 120 feed systems, meaning each system is supplied with its own yarn, producing a knitted loop course with each revolution of the machine. So, if there are 120 feeders, 120 courses are created in one machine cycle.

Knitting Machine Specifications: Knitting machines are defined by three main features:

- Working Diameter (for circular machines) or Working Width (for flat machines):

- The diameter is the distance across the needle bed of a circular machine.

- The working width measures the distance between the first and last needle in a flat machine.

- Needle Gauge or Pitch:

- This measures the number of needles per inch in the needle bed. Finer gauges mean more needles, leading to finer fabrics, while coarser gauges result in thicker fabrics. The highest needle gauge is around 60, while the lowest is 2-2.5.

- The “needle pitch” is the distance between two needles, and this affects the thickness of yarns that can be used on the machine.

Selvedged and Cut Edge Fabrics:

- Selvedged Fabric: This fabric has a self-finished edge, created by knitting in a way that the yarn wraps around and forms the edge.

- Cut Edge Fabric: This is typically produced by cutting open a tubular fabric, commonly done in circular knitting machines.

Tubular Fabric: This type of fabric can be made in either single or double-faced forms on circular machines. It’s formed as a continuous tube, with the yarn joining the fabric at the edges to create a seamless structure.

Warp Knitting (Laps): In warp knitting, the term “lap” refers to how the yarn wraps around the needles. An open lap occurs when the yarn loop overlaps in the same direction, while a closed lap creates a denser, less stretchy fabric. Open laps result in lighter, more flexible fabrics.

Open Lap: An open lap is formed when the yarn’s underlap follows the same direction as the overlap, or when the underlap is skipped altogether. This means the next overlap starts where the previous one ended. In contrast, closed laps are denser, heavier, less flexible, and less see-through compared to open laps, even when using the same yarn and knitting method.

Closed Lap:

A closed lap happens when the underlap moves in the opposite direction to the overlap, wrapping the yarn around both sides of the needles.

The Overlap:

The overlap is created when a warp guide moves the yarn across one needle hook, shaping it into the top of the loop. This action, combined with the guide’s back-and-forth movement, forms the two sides (or legs) of the loop. On the front side of the fabric, this looks similar to a loop made in weft knitting. Essentially, the overlap is the part of the yarn that goes over the needle during loop formation in warp knitting.

The Underlap:

The underlap occurs when the yarn is laid across the side of the needle opposite the hooks, moving in between overlaps. It connects the yarn between two overlaps in consecutive rows, either on the front for single-bar machines or in the middle for double-bar needle machines. Both underlaps and overlaps are crucial in warp knitting, as they bind the loops (or wales) together. Different guide bars may control the overlaps and underlaps, depending on the fabric structure.